Written By Aaron Marion

I apologize for the lengthy hiatus from the Mechanics Blog. I have been incredibly busy personally and

professionally and it’s all been great! Today I was visiting with one of our premium members about

some concerns he had with his employer, and I told him my favorite catchphrase: the title of this article, A Reasonable Expectation IS a Reasonable Expectation.

It’s something that is often overlooked but, in my opinion, should be expected as a two way street

between employer and employee. A lot of talk is talked about tech pay and percentages and numbers

and dollars and very little is ever said about expectations. EVERY tech on the market wants to be fairly

compensated. EVERY owner wants to keep his techs busy, fed, and profitable. But I find that (often

enough to write about) clear expectations are not being discussed.

How do we define these expectations? Here’s a few of my personal recommendations for Techs and

Hiring Managers.

The Tech should ask themselves a few questions first and be honest even if it hurts.

- Decide on a dollar amount ANNUALLY that will keep you financially whole.

- If you don’t know this, an assessment of your finances is step 1

- Divide that by 52 weeks. Now you know how much per week you need to make.

- Is that a number you can satisfy at your current skill level in 40 hours? (Be

honest even if it hurts. Honesty is valuable - sometimes even in dollars.)

- Are you willing to work more than 40 hours if your answer to the previous

question was “No”?

- Are you willing to work more than 40 hours, period?

-Do you have any certifications? Like it or not, you’re going to be asked this in an

interview. I’m tired of seeing people complain about not getting hired or getting offered

too little while they dog on certifications. It’s the only thing besides your work history

that can be judged in a conversation. It shows your commitment to the craft. It helps

validate the services you perform for your employer. I strongly recommend it if you truly

want that top paying position.

-Are you efficient? Can you complete a repair in book time? Lots of people will say yes,

but the numbers prove otherwise. Is it the repair or your in-bay time management?

OUCH. Are you in an area plagued with rust and repair times are not adjusted

accordingly?

- Do you have tools? Not just a paper sack with some garage sale stuff in it. (Another

story for another day.) Do you have the tools to perform the work you want to be paid

for? It sounds like a redundant question, but I’ve seen it time and time again. The

majority of our industry is still requiring techs to have their own tools. Techs show up

on day one inadequately prepared for the work that they said in the interview they

could perform. Not to let this become a tool discussion — that’s for another day as

well. But when a tech is hired as an A or B level tech and they are borrowing sockets

and drill bits on day one, it’s concerning.

- Can you diagnose? Now this one I’ll spend some time on because it’s near and dear to

my heart and I’m tired of this question being cornered into a three word sentence. But

can you? Do you have a fundamental understanding of Automotive systems and their

operation? Can you read service information and understand how a system is operating

in order to ascertain where a problem lies? And the real kicker: Can you communicate

and validate the substantial amount of time it often takes to solve these problems? The

“ole 1 hour diag” is going away. It’s becoming less and less prevalent and we will soon

see it phased out entirely. Good riddance. Sales is tricky, and good salesman (your

service advisors) want as much data and information as they can get to aid in their

ability to confidently sell your expensive labor. Effective communication is one of the

best skill an automotive tech can possess. If you’re in the stone ages and unwilling to

communicate the diagnostic and testing needs the vehicle has, I hope you enjoy doing

brakes. It’s 2022, the age of information. The consumers want ALL of the information.

If you can’t compile it efficiently and effectively, you’re going to struggle.

- Are you punctual and professional? Are you on time? Are you neat, clean, and ready to

work? Are you hung over until 10:00? Do you spend an hour and a half on the porcelain

throne surfing Mechanic Alliance Facebook page during work?

- What is the market in your area? Cost of living adjusted pay is something for another

time, but don’t expect ridiculous percentages or assume that X percent is industry

standard. A good tech should make a good comfortable living. That number is different

for everyone and you as an individual have to asses that, along with your current market

and decide on a dollar amount.

Now, you’ve asked yourself these questions, and I hope you’ve answered honestly, because these are the

expectations that the people who are hiring you have. These are the questions they forget to ask but

assume are part of the gig. These are the things that they are going to be upset about should you falter

in any areas. You’ve been warned.

The Manager/Owner should be prepared to ask themselves a few questions as well.

- Why do you need to hire a tech? Number one, straight to the point. Often missed.

Often confused. Why? Techs should be asking this question in every interview.

- Are you leaving work unfinished every week?

- Do you have extra bays?

- Do you want to grow?

- Do you have a tech who needs replaced?

- Do you have an opening because someone left? Why did they leave?

- Do you know your numbers?

- P&L, ARO, Gross, Net, etc etc. The guy you want to hire wants to know these

numbers, you should know them well.

- Break a months repairs down by ASE. Are you doing 75% brakes and

suspension? Are you doing 30% drivability? This simple question may really help

you find the guy you need instead of hiring someone you THINK you need. For

example, lots of shops advertise wanting an L1 with 50 years of experience and

the entire AES Wave catalog when they actually NEED someone who’s good at

suspension and alignments.

- Is your “culture full of vultures”?

- Lots of shop owners brag about their culture but if employees were surveyed it

might produce a different perspective. It’s hard to get an accurate assessment.

My favorite assessment is longevity of employees. It’s kind of like ASEs. Not the

most accurate way to gauge a shop, but it’s what we have so it’s what we use. If

you don’t want to be judged by the length of time your employees have been

with you, don’t judge a tech by the number of shops he’s been at.

- Are you financially capable of offering a top level compensation package? Another

honesty checkpoint. Some shops aren’t aware of their profitability and aren’t aware

that they can’t actually afford a six figure pay with benefits and PTO. Yet they hire

hoping that they are going to find a magic tech who can make all of their problems go

away and they promise the moon only to have the tech quit after 90 days leaving a

bitter taste in everyone’s mouth.

-Are your shop processes and fixed operations efficient? I’m tired of the “a good tech

should be able to make six figures anywhere” rhetoric. And the blame game rolls out

and nobody wants to be accountable, everyone wants to part ways. Nobody wins. But

a few key points to consider:

- Service advisor skills

- Parts supplier problems

- Shop layout including parking

- Equipment condition

- Amount of unbilled labor (including anything you offer for “free” doesn’t matter

if you charge on the back end, unbilled is unbilled and that’s how your techs see it)

- Shop equipment. Labor times are built assuming OEM equipment and tooling. I

recently spoke to a few people who were working without lifts. Flat rate hours,

being hassled about their times, working on jack stands. Do you have adequate

diagnostic tools or do you expect the tech to provide their own?

Now, this is not all encompassing, but I’m talking to a lot of owners and a lot of techs conducting 20

minute interviews, asking the most basic questions like “How much can you pay me?” and “Can you pass

a drug test?”

So for you techs on the job market, read and understand these questions. Be honest with your

capabilities and be willing to learn. Be honest with hiring managers. Inflating your skills for an extra $2

an hour isn’t going to help you. But also know your worth and don’t settle for less. If a shop has

problems answering these questions, and can’t explain their processes clearly, it may be prudent to

expand your search.

You folks doing the hiring and firing: get technical in your interviews. Ask hard questions. Have one of

your stud techs help you if you don’t know the hard questions to ask. Best yet, have Mechanic Alliance help you!

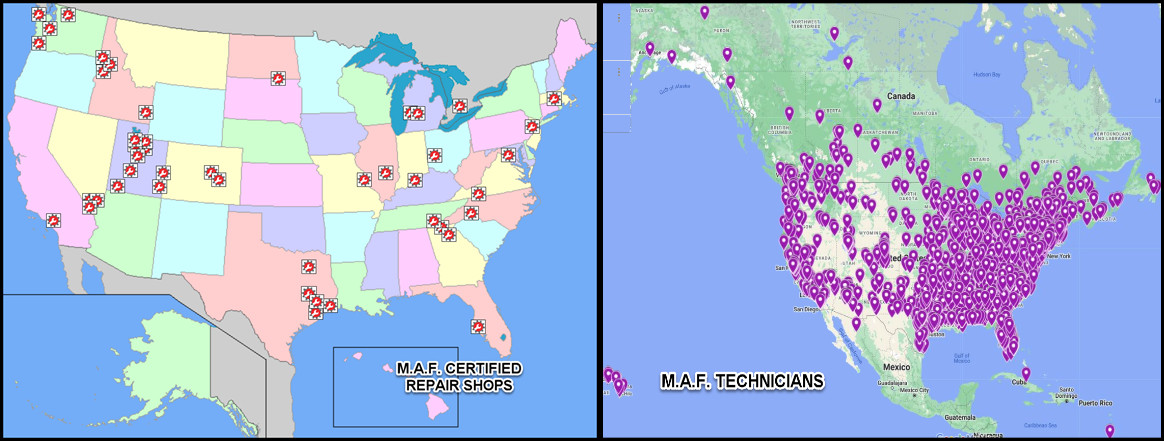

We have resources for not only finding techs but also helping you assess your needs and their skills. A

reasonable expectation for a paycheck should always come with a reasonable expectation for services

rendered. It should be clear, quantifiable, and agreed upon by both parties. It’s reasonable to expect!

Join the Alliance Here!

Shop Owners take a look at what joining the Alliance can do for you!